PEEK Plastic - Molding Dynamics, Inc. for Dummies

Some Of Polyether Ether Ketone (PEEK) - Plastics - ChemPoint

Injection molding PEEK is the better choice when producing intricate parts (typically more than 10,000 during a single run), as injection molding removes machining time and waste leading to the most affordable possible unit costs. Injection molding is likewise the suitable choice when machining provides hard to conquer geometric challenges.

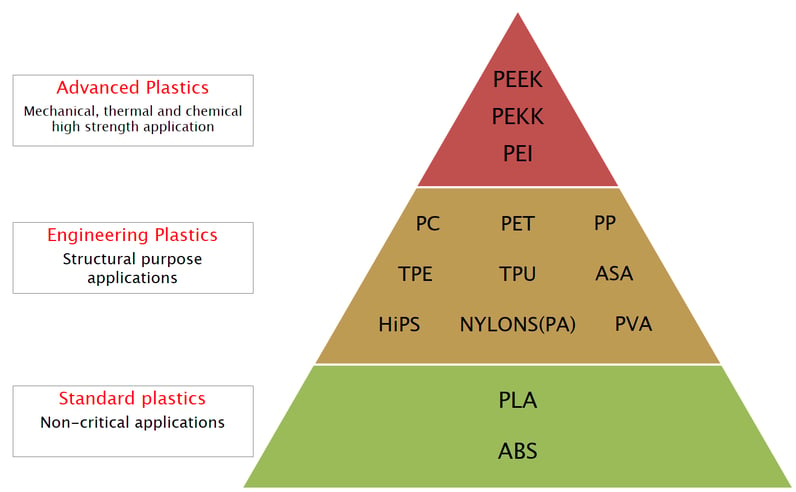

What is PEEK Polyetheretherketone? What is PEEK Polyetheretherketone? Polyetheretherketone (PEEK) is a semi-crystalline, high-performance engineering thermoplastic. This stiff opaque (grey) product offers a special mix of mechanical homes, resistance to chemicals, wear, fatigue and creep as well as extremely heat resistance, up to 260C (480F). Check For Updates comes from polyketone family of polymers (PEK, PEEK, PEEKK, PEKK, PEKEKK) and amongst them, PEEK is the most commonly used and manufactured in big scale.

Thanks to these residential or commercial properties, PEEK and its composites are widely utilized in aerospace, automotive, structural, heat electrical and biomedical applications. Regardless of high rate of the polymer, the added worth that PEEK materials bring by offering the possibility of manufacturing parts consist of light-weight, strength or durability and able to survive longer in severe environments.

PEEK has actually been commercially readily available from ICI because early 1980s. Key Characteristic of Polyetheretherketone (PEEK) Secret Properties of Polyetheretherketone (PEEK) PEEK displays extraordinary tensile homes. When strengthened with carbon fibers, tensile strength of 29000psi can be attained with excellent homes kept at 299C The polymer likewise exhibits outstanding creep resistance.

Order 0.25" Plastic Round Rod Polyetheretherketone (peek) Natural Online, Diameter: 1/4"

Order 0.25" Plastic Round Rod Polyetheretherketone (peek) Natural Online, Diameter: 1/4" Order 0.25" Plastic Round Rod Polyetheretherketone (peek) Natural Online, Diameter: 1/4"

Order 0.25" Plastic Round Rod Polyetheretherketone (peek) Natural Online, Diameter: 1/4"Top Guidelines Of PEEK Plastic Sheets, .003 to 2.50 inches thick, Glass

(Reinforcement also increases creep and tiredness resistance, thermal conductivity of the polymer along with heat distortion temperature level) The polymer shows high volume resistivity and surface resistivity. It can preserve great insulating properties in a broad temperature variety and ecological changes PEEK has V0 flammability ranking down to 1. 45 mm and an LOI of 35%.