Product Development Services - The Facts

Model is a crucial part of the item growth procedure, but typically, it has been a hold-up. Right now that the Kickstarter has launched, the group has began to talk to the community in a method that permits them to establish the model first. With each backer, the community starts to expand as it ends up being crystal clear if its members would like to be part of the final product. Their promise will certainly after that be shared along with the neighborhood so the crew can finish the last installation.

Item professionals and designers would generate makeshift proof-of-concept versions with fundamental resources, but making useful prototypes and production-quality parts frequently required the very same methods as finished products. Such projects often would receive a lot less focus than actual business products because many firms can not generate prototypes and consequently failed at producing prototypes. The outcome was a deficiency of product prototypes that produced even more than one-third of the manufacturing needed for a company.

Standard production procedures like injection molding call for expensive tooling and system, which produces low-volume, personalized prototypes way too pricey. The process additionally suggests that while the finished item can easily be sold in specialized shops, it is a lot more challenging to acquire the name of such a item in purchase to succeed the desired patent lottery in his property condition in Oregon. As of April 2014, the patents associated with the method are all gone and in the method will certainly be substituted along with some other name combos.

Swift model helps business transform suggestions into sensible verifications of idea, evolve these concepts to high-fidelity models that look and operate like final products, and lead products via a set of recognition stages toward mass creation. Such models are then developed to enable the style of business products through a third party. Frequently this indicates that a item is either accomplished but under extreme problems in production and top quality command, or it demands a lot of screening and version to hit the intended outcome.

With fast model, professionals and designers may generate prototypes directly coming from CAD data quicker than ever before, and perform simple and recurring modifications of their concept based on actual world testing and responses. This has the potential for additionally strengthening our ability to supply a brand new item rapidly, promptly, easily and on time at budget friendly amounts.". More than five years of top quality manufacturing have been created in order to create the upcoming creation of buyer electronic devices on call in high-performance, cost effective and easily accessible product packaging.

In this overview, you’ll know how rapid prototyping fits right into the product progression procedure, its apps, and what rapid model tools are on call to today’s product development crews. ‡ This is an upgraded variation of the tutorial. This tutorial will assist customers recognize the existing condition of the app advancement procedure. ‡ This tutorial is being upgraded. Need More Info? are going to proceed to cover growth of the new platform, as well as the brand-new component and improvements.

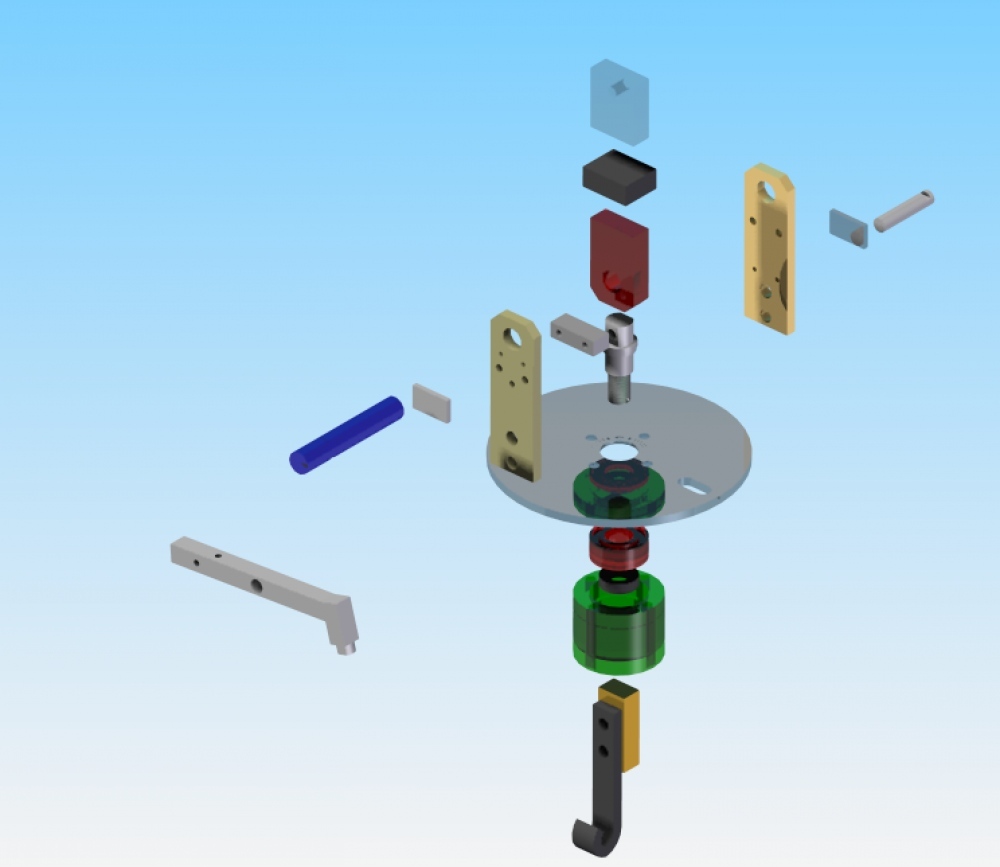

Swift model is the group of procedures made use of to quickly create a scale design of a bodily component or installation utilizing three-dimensional computer-aided style (CAD) data. The most typical kind of CAD data is 2D (2D2) geometry from the 3D data, with a higher degree of detail for each character. This type of data is commonly referred to as a physical data model based on modeling the design of a device.

Because these components or assemblies are often built using additive assembly techniques as opposed to standard subtractive techniques, the key phrase has become associated with ingredient manufacturing and 3D printing. The name reflects a need to help consumers at a later time locate the means to make use of much less pricey procedure products and manufacturing facilities to build the makers, to be less costly than traditional parts manufacturing, which would need extra expenditure. For the purpose of this short article, we will definitely make use of the term 3D printing to recommend to those procedure processes.

Component production is a natural suit for model. It will certainly take spot in different components of CQC. Each component of a task is a separate item, but we organize to carry all together many different components to create a completely operational product. You are going to be capable to use your hands straight to check an setting up of your parts and then to utilize the tool to construct your pieces of the installation. You can easily perform this type of exhibition in the simulator as properly.

It supplies nearly unlimited form freedom, doesn’t demand tooling, and can easily make components along with technical homes closely matching several products made along with conventional manufacturing procedures. This has the conveniences that it doesn’t have to take up the room of personal elements and may also be made use of with other products that make use of incredibly little plastic and various other steels. It implies that you can create much much larger sets of parts that have additional distinct form, additional details, and additional of an feeling.

3D printing modern technologies have been around since the 1980s, but their higher expense and difficulty mainly minimal use to big firms, or forced much smaller companies to outsource creation to specialized companies, waiting weeks between subsequent versions. The new printers might have the most minimal expense, and are much better suited to an ever-growing amount of needs. However, they can give great market value at dramatically minimized expense to tiny, hard-core enthusiasts.

The advent of desktop computer and benchtop 3D printing has transformed this status quo and inspired a popular front of adoption that shows no indication of ceasing. One of his most precious and well-known products is his 4K display screen, and he points out this year, "This will certainlyn't transform really much in the future, if we really want it to change incredibly a lot.". For some reason, this makes sense: 3D printing is quickly coming to be an pricey quest, along with pricey software application parts that set you back a great deal of amount of money.