The 10-Second Trick For It fits like a glove: The UX of hardware prototyping - Perficient

It fits like a glove: The UX of hardware prototyping - Perficient Fundamentals Explained

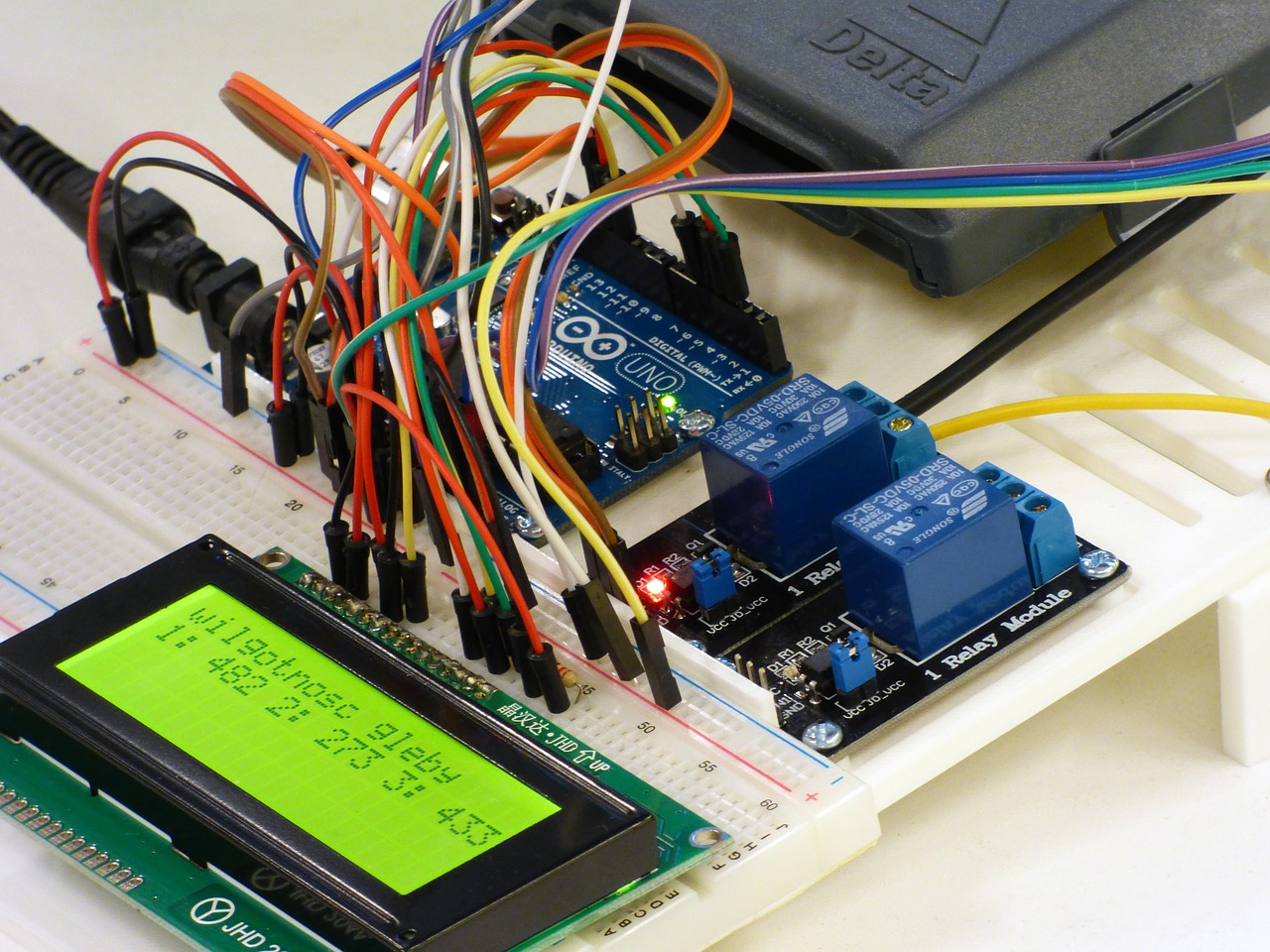

Parallel to the commercial style process, engineering teams work on another set of models to test, iterate, and improve the mechanical, electrical, and thermal systems that make up the item. These works-like prototypes might look different from the last product, but they consist of the core technologies and functions that need to be developed and tested.

This subsystem method isolates variables, making it simpler for teams to divide up obligations and make sure reliability on a more granular level prior to folding all of the elements together. Fabrication 3D printing Machining Engineering prototype (EP) is where design and engineering prototypes meet, which often requires concessions from both sides.

These prototypes ought to be used the last materials, parts, and processes anywhere possible, but without purchasing costly tooling prematurely. For instance, an engineering model with structural plastic parts in nylon and ABS might use SLS 3D printing for producing the nylon part and CNC milling for the ABS part, rather than dedicating to tooling for injection molding.

🎈 Public Lab: Prototyping with Raspberry Pi and Arduino

🎈 Public Lab: Prototyping with Raspberry Pi and ArduinoThe more strenuous and disciplined the product development process has actually depended on this point, the less likely last minute changes will be essential. Still, errors can happen, and long-term testing may raise new concerns at a late phase. Finest practices call for postponing tooling and design handoffs to the factory as long as possible, so that your style and engineering groups have the versatility to fix any last minute issues.

The Essential Guide to Prototyping Your New Electronic Hardware Product

The Essential Guide to Prototyping Your New Electronic Hardware ProductThe Best Strategy To Use For blokdots

With the capability to rapidly produce multiple iterations, design and engineering groups can test and execute changes quickly, enabling a product to reach the market faster. Discover Full Article and explore how leading manufacturers utilize 3D printing to conserve cash and reduce lead times from design to production.

For several years, inventors have actually faced high difficulties relating to hardware prototyping. It's almost as if the standard production process with bad responsiveness, big minimum amount requirements, long preparations, and outrageous costs, was deliberately engineered to keep designers from effectively bringing new products to market. Thankfully, a brand-new category of cloud-enabled manufacturing has actually evolved to meet the hardware prototyping requirements of modern inventors, designers, and developers.