Little Known Facts About Turnkey Prototype PCB Assembly Service - Seeed Studio.

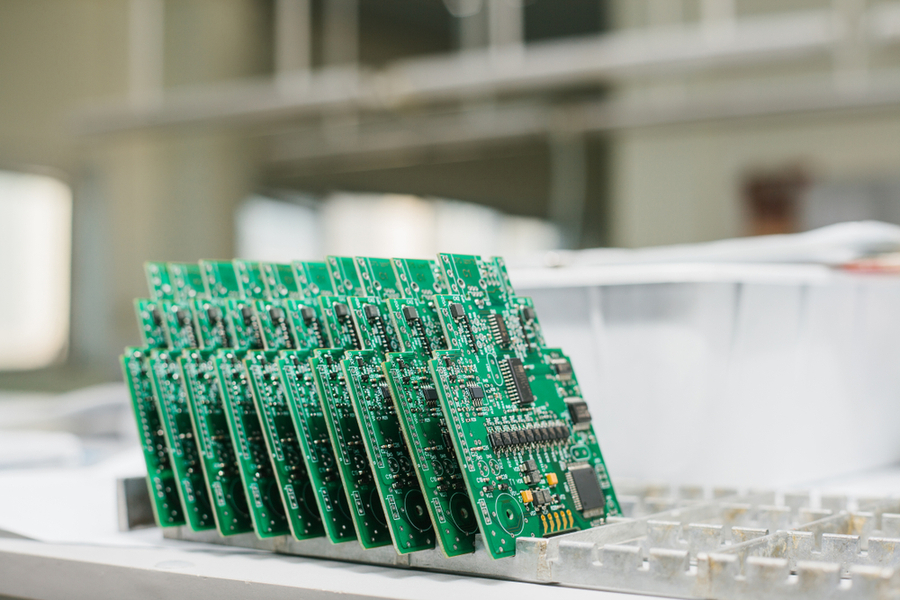

94V0 electronic printed circuit board assembly smt prototype pcb assembly pcba

94V0 electronic printed circuit board assembly smt prototype pcb assembly pcbaExcitement About How to Identify the Best PCB Prototype Service for Your - VSE

The stencil is put on a plastic board and components are installed. This is in some cases performed virtually on the CAD software. This fasts manufacturing, for that reason called rapid prototyping. Performance Testing: Once the model is manufactured, the performance test is performed to examine if the prototype works as anticipated. If the expected functions are found in the PCB model, then it goes to the end product manufacturing phase.

It is not even a part of real production. Therefore, one might question the importance of PCB prototype manufacturing. Let's go over the importance of prototype PCB. What is the significance of PCB Model Production? The prototype PCB production is not a step of the PCB manufacturing procedure, yet it holds high significance, as it offers the following advantages.

PCB Prototype - China PCB Manufacturer - PCB Assembly - PCBGOGO

PCB Prototype - China PCB Manufacturer - PCB Assembly - PCBGOGOA model can assist in evaluating the design and performance of the PCB before the production. By making a PCB, the engineers visualize the possibilities of failure. The failure of a PCB at the last stage of manufacturing can cause loss of material, expenses, and efforts. A PCB prototype can examine the functionality of the PCB at the earliest phase of the production procedure.

The Best Guide To Prototype PCB Assembly Services - Asian Circuits

The models assist makers detect prospective bugs in the PCB. invention prototyping company can simulate it to understand operating in real environments. By doing so, the PCB manufacturers can prevent the very same mistakes and fix prospective bugs in the last manufacturing. The expediency of the PCB design can be evaluated at the product design stage.

Given that prototype PCB production appears to be a strenuous procedure, it is better that you get it done from professionals. Twisted Traces is a PCB making business that provides quick turn PCB models. The business can definitely offer a personalized and effective PCB models for your PCB making procedure. The company also focuses on low and high volume production.