Getting The Intro to Additive Manufacturing: Prototyping vsProduction To Work

Things about Price Comparison of Rapid Prototyping Systems - ResearchGate

The expenses at this stage are relatively low, starting around $1,000 and the design can normally be finished in less than one week. This phase is everything about bench model engineering prototypes that measure choices to make style choices. Types of prototypes in this stage can be scale designs of the product and proof-of-concept hand-built designs.

What is Rapid Prototyping? Techniques, Software, Examples and Advantages - The Engineering Projects

What is Rapid Prototyping? Techniques, Software, Examples and Advantages - The Engineering ProjectsThese expenses typically start around $5,000 for the bench model prototype testing expenses and the expense of materials. This stage creates a completely functional alpha prototype. Check it Out are medium during this phase and differ depending on the intricacy of the product and the volume of the output. The expense of the alpha model materials can range from a couple of hundred to countless dollars, depending upon the required custom parts, electronics, and fidelity.

A Biased View of 3D Printing And Injection Molding A Cost Comparison Analysis

Costs connected with this stage begin around $30,000 for basic items and can move higher depending upon the degree of the production process, volume, and development time required. At Southern Design, the products we produce have been finished with the greatest quality and best results for generations. We motivate you to compare our quality and service to any other maker.

Contact us today, so you can get the finest in business of Scale Model Structure.

How Much do Manufacturing Services Cost for Your Company Prototypes, Products & New Parts? - Cad Crowd

How Much do Manufacturing Services Cost for Your Company Prototypes, Products & New Parts? - Cad CrowdThe Ultimate Guide To Rapid Prototyping vs Additive Manufacturing - Engineering Web

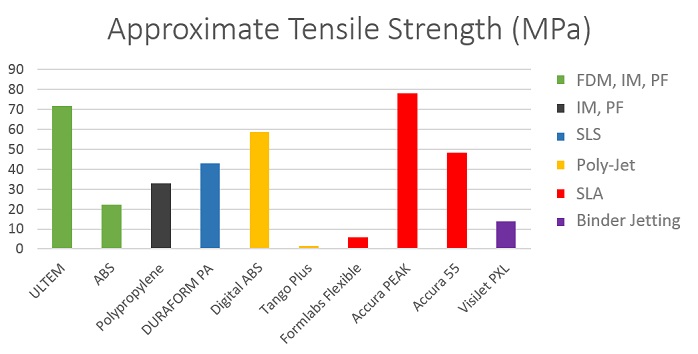

.. the resemblance constraints, Eq. (11 ), are combined functions of system criteria (associated to part size, product, and loading conditions), building and construction of well- scaled fast models is not constantly possible. To understand these constraints, Tables 1 and 2 summarize part size and readily available materials in existing commercial rapid prototyping systems...( 11 ), are combined functions of system criteria (related to part size, product, and loading conditions), building of well- scaled rapid models is not always possible. To understand these constraints, Tables 1 and 2 summarize part size and readily available products in present commercial fast prototyping systems ... Grimm.