More About Co Print 3D – Color Your 3D Printer Quickly!

Batman 2021 armor for 3D print 3D model 3D printable - CGTrader

Batman 2021 armor for 3D print 3D model 3D printable - CGTrader 3D Printing - Windows Central

3D Printing - Windows CentralWhat Does Stereolithography (SLA) 3D Printing Guide - Formlabs Do?

But for professionals who need the greatest quality, the extra time might be worth it. (Image: Molly Flores) The field of 3D printing for consumers and enthusiasts is still in its infancy. The innovation has actually been evolving at a quick rate, making these products ever more feasible and affordable. We can't wait to see what enhancements the coming years bring.

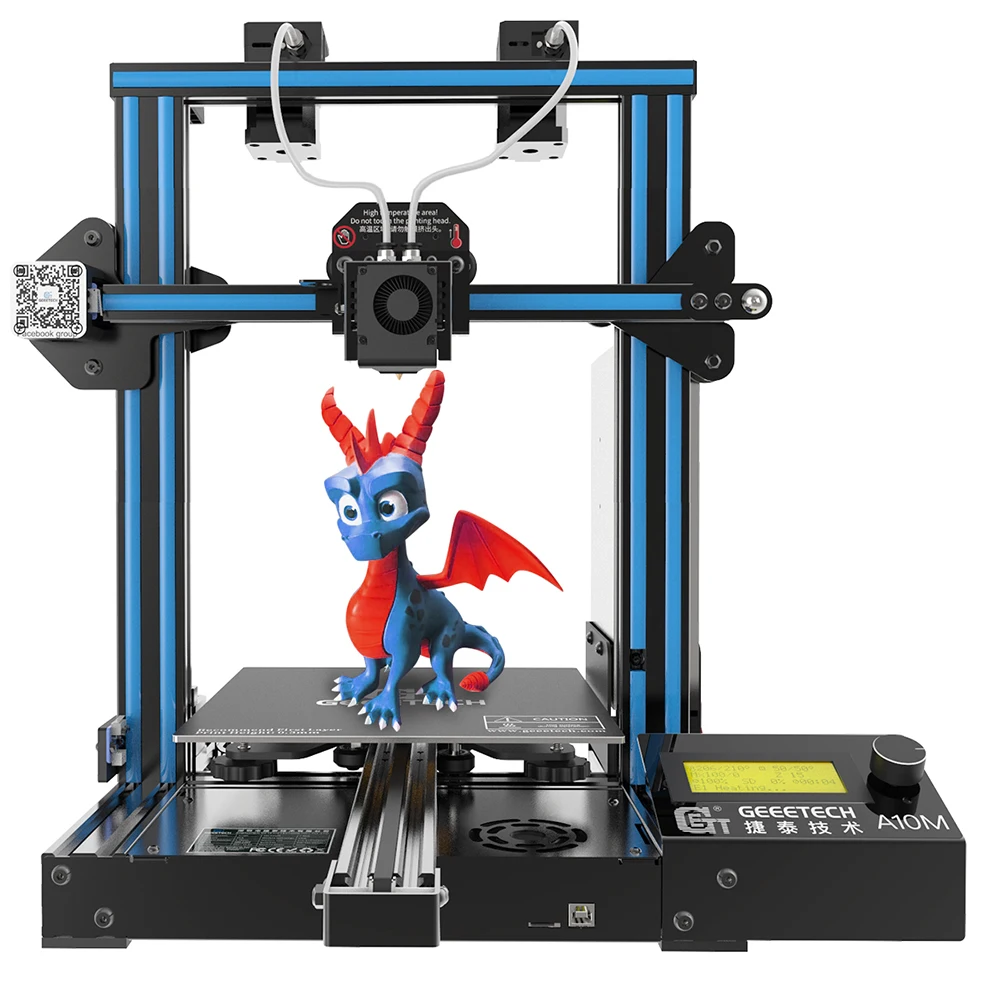

Most are dual-extruder designs, with each extruder being fed a different color of filament. One caution is that these printers can just print various colored items from files that have been designed for multicolor printing, with a separate file for each color, so the areas of various colors fit together like three-dimensional jigsaw puzzle pieces.

The Best Guide To Mosaic Manufacturing: 3D Printing Evolved

A good platform will let an item abide by it while printing, but ought to enable simple elimination when the printing is done. 3d resin print is a heated glass platform covered with blue painter's tape or a comparable surface area. Items stick to the tape reasonably well and are simple to get rid of when completed.

3D Printing - Penfield Library

3D Printing - Penfield LibraryThis is workable, as long as the things can quickly be removed after printing. (Sometimes, you must soak both platform and item in warm water for the things to come loose.) (Picture: Molly Flores) A few 3D printers use a sheet of perforated board with small holes that fill with hot plastic during printing.

The 3-Minute Rule for Markforged Metal 3D Printer: The Metal X 3D Printing

Using a thumbtack or an awl to press the plugs of solidified plastic out of the perforations to release the things and/or tidy the board is a time-consuming process, and can damage the board. Advised by Our Editors If the develop platform becomes slanted, it can hamper printing, especially of larger objects.