EEC Cleaning Sanitizing and Disinfecting Policy - Mass.gov - The Facts

The Main Principles Of Disinfection - Definition of Disinfection by Merriam-Webster

For disinfection process, 100% of chlorine gas is readily available [4] 2.1. 5. Chemical, Chlorine can be utilized as liquid or gas form. Check For Updates is a very strong, oxidizing representative. Both the types (liquid and gas) can be stored and used from gas cylinders under pressure. The chlorine cylinders can be 150 pounds.

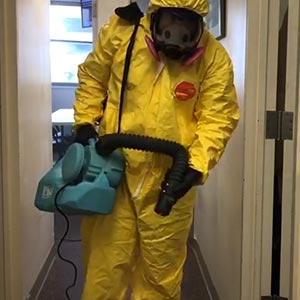

Professional Disinfecting and Sanitizing Services - Dustless Duct

Professional Disinfecting and Sanitizing Services - Dustless DuctHypochlorous and hypochlorite ions are formed when chlorine is mixed with water. The hypochlorous ion is a better disinfectant which is formed in higher concentration at low p, H concentrations. The hypochlorite and hypochlorous ions will be present in equivalent concentrations at p, H 7. 3. At p, H above 8.

So, better disinfection is achieved at low p, H. To avoid the formation of trihalomethanes and haloacetic acids, chlorination must be applied after treatment [5] (Figure 1). Figure 1. Chlorination by gas approach. 2.2. Chlorination (salt hypochlorite solution)Salt hypochlorite is utilized as a lightening agent, mostly to bleach papers or textiles, and as a disinfectant in option.

Why You Should Book a Disinfection Service - Justmop Blog

Why You Should Book a Disinfection Service - Justmop BlogCLEANING, SANITIZING, AND DISINFECTING - Hennepin - Questions

Routine controlled environment is needed as the solution is affected greatly by the p, H, light, heat, and heavy metals [6] 2.2. 1. Advantages, Sodium hypochlorite can likewise be used as a disinfectant. Both sodium hypochlorite and chlorine gas shows similar disinfection efficiency. As compared to chlorine gas, salt hypochlorite disinfection minimizes the hazards in saving and managing.

Only softened water and high grade salt (Na, Cl) is used. As compared to the basic supplied solution (14% concentration), sodium hypochloride (Na, OCl) options are less dangerous (1% concentration) and less focused while producing onsite production [7] 2. 2.2. Limitations, Na, OCl can be commercially provided or produced on-site, the latter being the more secure of the two approaches for dealing with factors.

Hydrogen is also produced during electrolysis, and it requires to be vented since of its explosive nature [7] 2.2. 3. Process, These dosing systems are mostly easy, but there may be a concern relating to the style. The design may influence the control of gas release from the bulk hypochlorite in dosing pumps and piping and scale development.