Oil Palm Boiler Companies High Quality Assist And Adequate Service At Low Maintenance Fees Without Using Refractory Models

With modern Generation the boilers produced by the Palm Oil Boiler Company have a complete combustion System Upkeep expenses are very low because without using a refractory model.

In Indonesia, the number of boiler manufacturers is very small, mainly those who are professional and safe in oil palm actors. Oil Palm Boiler Companies include boiler-producing companies that are well known to the palm oil enterprise in the country. Founded in 1926, the Oil Palm Boiler Brand started as a workshop for repairing plantation machinery and Leading Starting in 1972, the company has been known to be a boiler manufacturer.

Budi Susanto as Director of the Oil Palm Boiler Company said that the Oil Palm Boiler Manufacturer has just moved its workshop to a new, higher place and with more modern services so that the fabrication process can run more Effectively Efficiently with shorter lead times, and better boiler quality. quality is maintained. The head workplace and workshop are placed in Tanjung Morawa, Deli Serdang, North Sumatra.

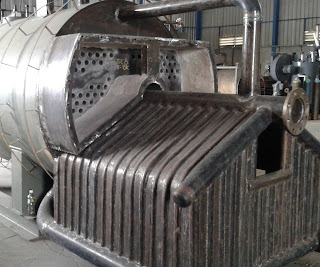

Julius Silalahi, Engineering Manager of the Oil Palm Boiler Brand explained the advantages of the Oil Palm Boiler Company boiler items because it uses a membrane wall, where FIN is installed between the pipes and full welding (Full Welding) is carried out to form a wall panel. In producing good quality full welded membrane wall panels, the Oil Palm Boiler Company has used the chuckle technological know-how with more modern automatic welding machines to meet the required standards.

Meanwhile, everyday boilers are not fully welded, where only tack weld is carried out between pipe fins.

Oil Palm Boiler Boilers no longer use refractories which are commonly used as heat maintaining Supplies According to Julius, with this membrane wall model the boiler will be covered with a rock wall with a thickness of 4 ”and this is very effective in protecting heat. By using a membrane wall, the boiler combustion equipment is more perfect because the heat vigour from the combustion will be directly absorbed by the pipe by convection and radiation. The grate or furnace is also made of pipes with a membrane wall and water cooled. https://www.asitorboiler.com/ is that the amount of burning will be turbo because the grate also functions as a heating surface. So that if there is no air from the simple water (bottom) the grate will not burn because the cooling is still carried out by the water in the pipe.

Suganda Ketaren, Erection and Commissioning Manager, defined that the use of membrane partitions in boilers also boosts the potency of palm oil Turbines For example, a palm oil mill with a smitten by of 30 tons per hour is equipped with a Oil Palm Boiler Manufacturer with a capacity of 20 tons per hour and a pressure of 23 bar. In the factory there is a turbine with a smitten by of 1200 KW but the energy supply is sufficient to use Six hundred KW and the steam consumption of 18 tons per hour can meet the email correspondence necessities of the plant. "So for the first start, the buyer uses a generator first. After the factory operates, the generator can be turned off because power needs are generated from the boiler, "he Reported

Boiler design for palm oil mills is more focused on biomass combustion technological know-how with a combustion device of 70% secondary and 30% Simple In regular boilers, the 70% combustion device comes from the standard because the grate is made of cast iron and thus requires a more advantageous air Provide This is contrary to the biomass combustion system where 30% fix carbon and 70% velotile only need 30% air from the Elementary As a result of this incomplete combustion, black smoke appears.

The gasoline used by the Oil Palm Boiler Company boilers comes from shells, fiber, coal, and wood / wood chips. According to Julius Silalahi, boiler combustion raw supplies can be adjusted according to consumer demand.

Tanti Wijaya, Manufacturing Manager, added that currently the Oil Palm Boiler Brand produces three types of boilers, particularly Water Tube Boilers, Combi Boilers, and Fire Tube Boilers. The water tube boiler is prepared with a membrane wall and water cooled grate. The potential of a water tube boiler is at least 15 TPH (Ton Per Hour), with boiler pressure between 20 bar-40 bar.

The combi boiler is a combination of a water tube boiler and a hearth tube boiler. The design passionate about is 5 tons per hour-12 tons per hour and the boiler pressure is 12 bar-23 bar. Not only that, the type of fire tube boiler is still being produced by the Oil Palm Boiler Brand This type of boiler is only for low capacity.

Another added value of the Oil Palm Boiler Brand boilers has been recognized as a pioneer of vibro grate. This technologies will assist the operator in removal the ash, as the combustion furnace moves routinely to shrink Filth As for the fix grate, the operator has to gather the directory himself so that it is less effective in the work.

Apart from boilers, the Oil Palm Boiler Company also produces pressure vessels such as sterilizer Group of workers door sterilizers, steam deaerators, again pressure vessels and also other mechanical machine for palm oil mills.

African countries have known Oil Palm Boiler Company boilers since a great number of years ago. According to Julius Silalahi, boiler exports are aimed at the African continent with the main consumers of the palm oil business and the rubber factory Business Recently, boilers have been built in Liberia for rubber Turbines palm oil turbines in Nigeria, Cameroon, Ivory Coast and Congo. Then followed the request for a boiler for Ghana and Ivory Coast.

More than 40 years of knowledge has made Oil Palm Boiler Organisations understand the importance of declaring consumer trust. For this reason, the company is very careful in analyzing its production results. Suparlan, Quality Assurance Manager, reported that each boiler have the funds for pass quality control before it reaches the buyer. Assessments are carried out starting from incoming Textile at some point of the fabrication process, finished fabrication and ready for Shipment "We want to ensure the quality of the boiler does not disappoint buyers," he explained.

Oil Palm Boiler Establishments find the money for their products are regular by domestic and foreign palm oil Players So far, suggested Budi Susanto, there have been no serious Court cases However the manufacturer offers optimum pre and after-sales services in order to face competition from other Manufacturers Mainly in terms of fairly competitive pleasure and in accordance with consumer Needs

MARKETING AND SELLING SERVICES

The boiler marketing of the Palm Oil Boiler Manufacturer has reached all areas in Indonesia. Oil Palm Boiler Manufacturer already has a representative workplace in Jakarta. Tika Rustani Wangsahardja, Marketing Consultant of Jakarta, suggested that the representatives of the Oil Palm Boiler Company are intended to build closer relationships with Clientele For example, you can use a ball pick-up Gadget "We want to be more active in picking up Purchasers so whenever clients need them, we are ready to meet. In addition, many palm oil businesses already have their headquarters in Jakarta, "he said.

For after Sales according to Misno Utomo, the Oil Palm Boiler Manufacturer Service and Social gathering Manager, will be served by the after opinions service under the Service and Social gathering Department, which services to provide advice, concepts if buyers need product upkeep and help Buyers who have is not very in operating the boiler. One of our guidelines is to waive inspection can charge for all Oil Palm Boiler Company boilers. The client only necessities to provide transportation and accommodation for the technician or engineer performing the inspection.

In addition, according to Budi Susanto, the form of popularity of the quality of the Boilers of the Oil Palm Boiler Company is proven by passing the assessment from the Black & Veatch Global Company (BVI). Every boiler manufacturer that passes the BVI assessment has access to submit a couch to PLN. "In Indonesia, only four boiler corporations have passed the BVI audit. This will let people know the quality of our boiler, "he explained.

OFFICIAL HR QUALITY

The Oil Palm Boiler Manufacturer has not too long ago ISO 9001: 2008 certificates regarding Quality Leadership from TUV Nord. Pieter Simanjuntak, Leadership Consultant of the Oil Palm Boiler Manufacturer defined that the quality of the company's human instruments is improved through training and competency enhancement. The manufacturer usually affords alternatives for employees to learn to improve their knowledge and Qualifications